Case Study: The Impact of Automated Print and Apply Labelers on Bag Production

In today's fast-paced manufacturing environment, efficiency and accuracy are paramount. One area where these qualities are particularly crucial is in the production and labeling of bags. This case study explores how the implementation of an automated system for printing and labeling bags, along with automatic barcode verification, has significantly improved operations for a leading manufacturer.

Background

The manufacturer in question produces a wide range of bags for various industries, including food, pharmaceuticals, and retail. With a high volume of production, the company faced challenges in maintaining consistent quality and accuracy in labeling. Manual labeling processes were prone to errors, leading to issues such as mislabeled products, delays in shipping, and increased labor costs.

Implementation of Automated Systems

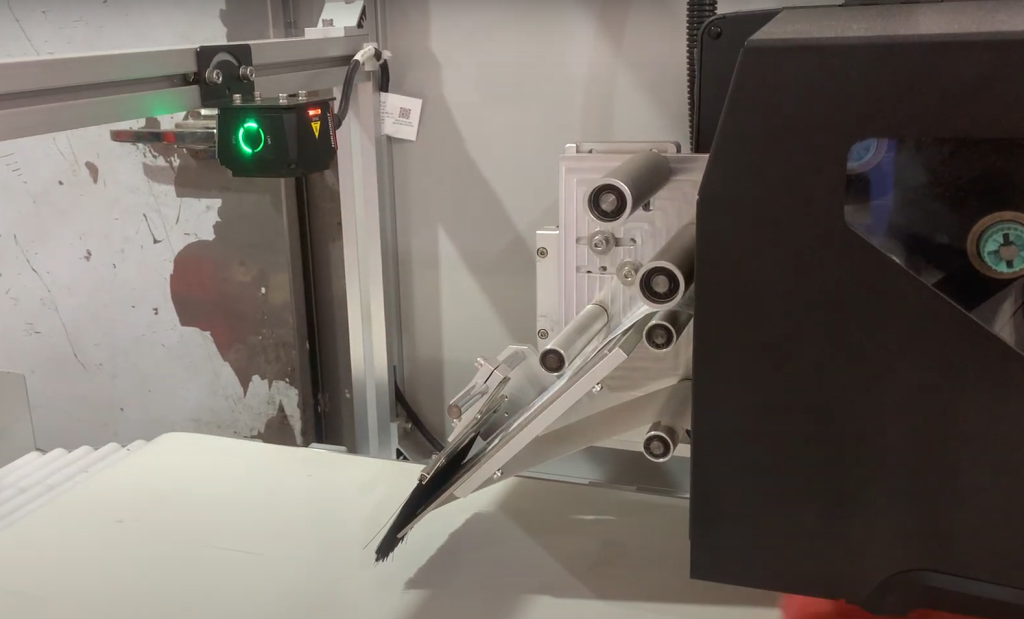

To address these challenges, the manufacturer decided to invest in an automated system for printing and labeling bags. This system included advanced printers capable of producing high-quality labels with variable data, such as batch numbers, expiration dates, and barcodes. Additionally, the system featured automated applicators to ensure precise placement of labels on each bag.

One of the key components of the new system was the integration of automatic barcode verification. After each bag was labeled, a scanner would read the barcode to ensure it was correct and legible. Any errors detected would trigger an alert, allowing for immediate corrective action.

Benefits received

The implementation of the automated printing and labeling system, along with barcode verification, brought several significant benefits to the manufacturer:

Increased Accuracy: The automated system drastically reduced the number of labeling errors. With precise control over the printing and application process, the company saw a significant decrease in mislabeled products. This improvement not only enhanced product quality but also reduced the risk of costly recalls and customer complaints.

Enhanced Efficiency: Automation streamlined the labeling process, allowing for faster production times. The system could handle high volumes of bags with minimal human intervention, freeing up employees to focus on other critical tasks. This increase in efficiency translated to higher throughput and the ability to meet tight deadlines more consistently.

Cost Savings: By reducing the need for manual labor, the manufacturer achieved substantial cost savings. Fewer errors meant less waste and rework, further contributing to cost efficiency. Additionally, the automated system's ability to operate continuously with minimal downtime ensured optimal use of resources.

Improved Traceability: The integration of barcode verification enhanced the traceability of products throughout the supply chain. Accurate and legible barcodes allowed for seamless tracking of each bag from production to delivery. This capability was particularly valuable in industries with stringent regulatory requirements, such as pharmaceuticals and food.

Scalability: The automated system provided the flexibility to scale operations as needed. Whether the manufacturer needed to increase production volumes or introduce new product lines, the system could be easily adjusted to accommodate changing demands. This scalability ensured that the company could grow and adapt without significant additional investment.

Conclusion

The case study of this leading bag manufacturer demonstrates the transformative impact of automated printing and labeling systems with barcode verification. By investing in advanced technology, the company was able to overcome challenges related to accuracy, efficiency, and cost. The benefits realized not only improved operational performance but also positioned the manufacturer for future growth and success.

In an increasingly competitive market, the adoption of automation in labeling processes is not just a trend but a necessity. Companies that embrace these technologies can expect to see significant improvements in their production capabilities, ultimately leading to better products and satisfied customers.