Quy mô sản xuất tuyệt đối tại CUSTOMER rất ấn tượng

Mỗi ngày, hơn 11.000 khung tản nhiệt được tinh chỉnh trên mỗi dây chuyền, khiến nơi đây trở thành trung tâm quan trọng cho sản xuất khung tản nhiệt trong khu vực. Khối lượng sản xuất lớn này đòi hỏi một hệ thống có thể xử lý số lượng lớn với độ chính xác và độ tin cậy. Đây chính là lúc các máy in và dán nhãn tự động của QKE Global phát huy tác dụng.

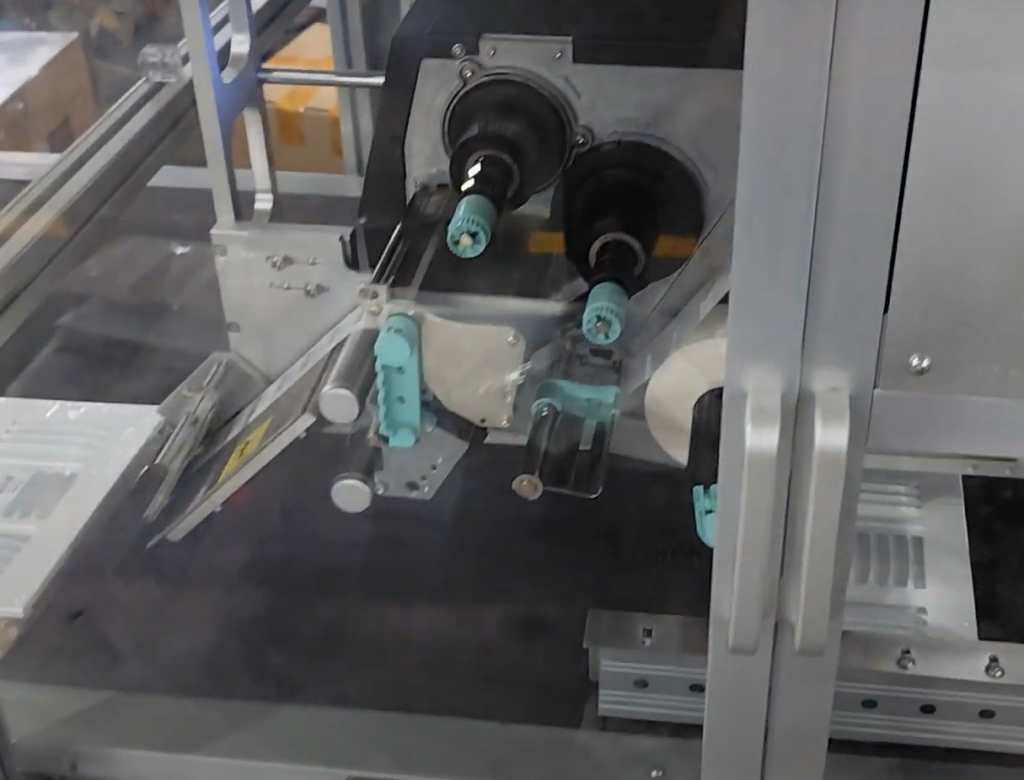

Vai trò của các trạm in và dán nhãn tự động

Các trạm in và dán nhãn tự động của QKE Global là một phần không thể thiếu trong quy trình sản xuất tại CUSTOMER. Các trạm này được thiết kế để xử lý toàn bộ quy trình dán nhãn, từ phân loại và cân đến xác minh mã vạch trên sản phẩm được đánh dấu. Mức độ tự động hóa này đảm bảo rằng mỗi khung tản nhiệt được dán nhãn chính xác, điều này rất quan trọng đối với việc quản lý hàng tồn kho, kiểm soát chất lượng và truy xuất nguồn gốc.

Công suất sản xuất của mỗi dây chuyền tại CUSTOMER lên tới 80 sản phẩm mỗi phút. Hoạt động sản xuất tốc độ cao này đòi hỏi thiết bị không chỉ nhanh mà còn đáng tin cậy và dễ sử dụng. Các máy in và dán nhãn của QKE Global đáp ứng các yêu cầu này, cung cấp giải pháp liền mạch và hiệu quả cho nhu cầu dán nhãn của nhà máy.

Các yếu tố chính: Thời gian hoạt động, Độ tin cậy và Dễ sử dụng

Đối với CUSTOMER, thời gian hoạt động, độ tin cậy và dễ sử dụng là những yếu tố chính để duy trì các tiêu chuẩn sản xuất cao của họ. Bất kỳ thời gian chết nào trong quá trình sản xuất đều có thể dẫn đến sự chậm trễ đáng kể và tăng chi phí. Do đó, thiết bị được sử dụng phải đáng tin cậy và có khả năng hoạt động liên tục mà không cần bảo trì hoặc hỏng hóc thường xuyên.

Lợi ích của Kiểm soát hoàn toàn

Một trong những tính năng nổi bật của các trạm đánh dấu của QKE Global là khả năng kiểm soát hoàn toàn toàn bộ quy trình dán nhãn. Điều này bao gồm phân loại khung tản nhiệt, cân chúng và xác minh mã vạch trên mỗi sản phẩm. Bằng cách tự động hóa các nhiệm vụ này, CUSTOMER có thể đảm bảo rằng mỗi khung tản nhiệt được dán nhãn chính xác và sẵn sàng để phân phối.

Mức độ kiểm soát này cũng nâng cao hiệu quả chung của nhà máy. Với việc phân loại và cân tự động, quy trình sản xuất trở nên hợp lý hơn, giảm nguy cơ sai sót và cải thiện tốc độ hoạt động. Xác minh mã vạch đảm bảo hơn nữa rằng mỗi sản phẩm được xác định và theo dõi chính xác, điều này rất cần thiết để duy trì các tiêu chuẩn chất lượng và đáp ứng các yêu cầu theo quy định.

Nâng cao năng suất và chất lượng

Việc tích hợp máy in và dán nhãn tự động của QKE Global đã nâng cao đáng kể năng suất và chất lượng sản xuất khung tản nhiệt tại CUSTOMER. Bằng cách tự động hóa quy trình dán nhãn, nhà máy có thể sản xuất nhiều khung tản nhiệt hơn trong thời gian ngắn hơn mà không ảnh hưởng đến chất lượng. Điều này không chỉ thúc đẩy sản lượng của nhà máy mà còn đảm bảo rằng mỗi sản phẩm đáp ứng các tiêu chuẩn cao nhất về độ chính xác và độ tin cậy.

English

English