Configurations and Types

Swing applicators are configurable via swing extend time, retract time settings, and taper options to optimize label placement timing. These adjustments enable precise control of label placement timing. Tamp/Swing features are enabled/disabled to switch between tamp and swing actions based on application needs. Correct set up optimizes motion profiles for smooth shifts during label dispensing.

Sensor inputs that use leading/trailing edge detection determine when the swing action triggers, and the acceleration/deceleration profiles guarantee smooth shifts during label dispensing. To prevent operational disruptions, configuration adjustments take place in offline mode. Swing timings are critical to optimizing the performance while maintaining label placement.

Label formats save and load variables such as web speed and tamp times for quick product swaps. With a password-protected setup menu it limits unauthorized configuration changes.

Key Use Cases

Key use cases for swing applicators span diverse industries, with deployments optimized for specific operational needs. Their flexibility provides substantial application benefits. Swing applicators automate labeling on diverse items, from consumer packaged goods to medical devices. Industry examples include logistics, manufacturing, and healthcare, each presenting unique challenges addressed by varied swing applicator designs.

| Industry Sector | Specific Application | Automation Impact |

|---|---|---|

| Logistics | Outbound shipping labels | Streamlines operations |

| Manufacturing | CPG labeling | Guarantees accuracy |

| Healthcare | Medical device labeling | Promotes compliance |

| E-commerce | Corner wrap labeling | Enhances traceability |

In e-commerce, automated address labeling on irregular packages improves efficiency and reduces scanning failures. Manufacturing uses swing applicators for high-speed labeling, minimizing errors on consumer goods. Medical device labeling benefits from precise placement on complex shapes, guaranteeing regulatory compliance. These systems provide consistent, reliable label applications, and reduce manual intervention.

Performance Attributes

Performance attributes of swing applicators determine their suitability across diverse operational contexts. Critical among these are speed metrics, which reveal maximum achievable throughput. In Wipe mode, the applicators reach 800 PPM Max, while E-TAMP mode delivers 120 PPM Max. Web speeds peak at 3,000 inches/minute in Merge applications, with line speed limits influenced by application type, such as 300 FPM Max for Wipe and 150 FPM for Tamp.

Accuracy benchmarks define placement precision. The adjustable timing parameters optimize label placement with minimal drift. In Tamp/BLOW applications, positional tolerance registers at ±2.4mm. Accuracy is further improved through Label Stop compensation, mitigating speed-related misalignments. Gap Sensor calibration guarantees label edge alignment within ±0.1mm. Encoder-driven Merge systems maintain consistent accuracy.

Operational Features

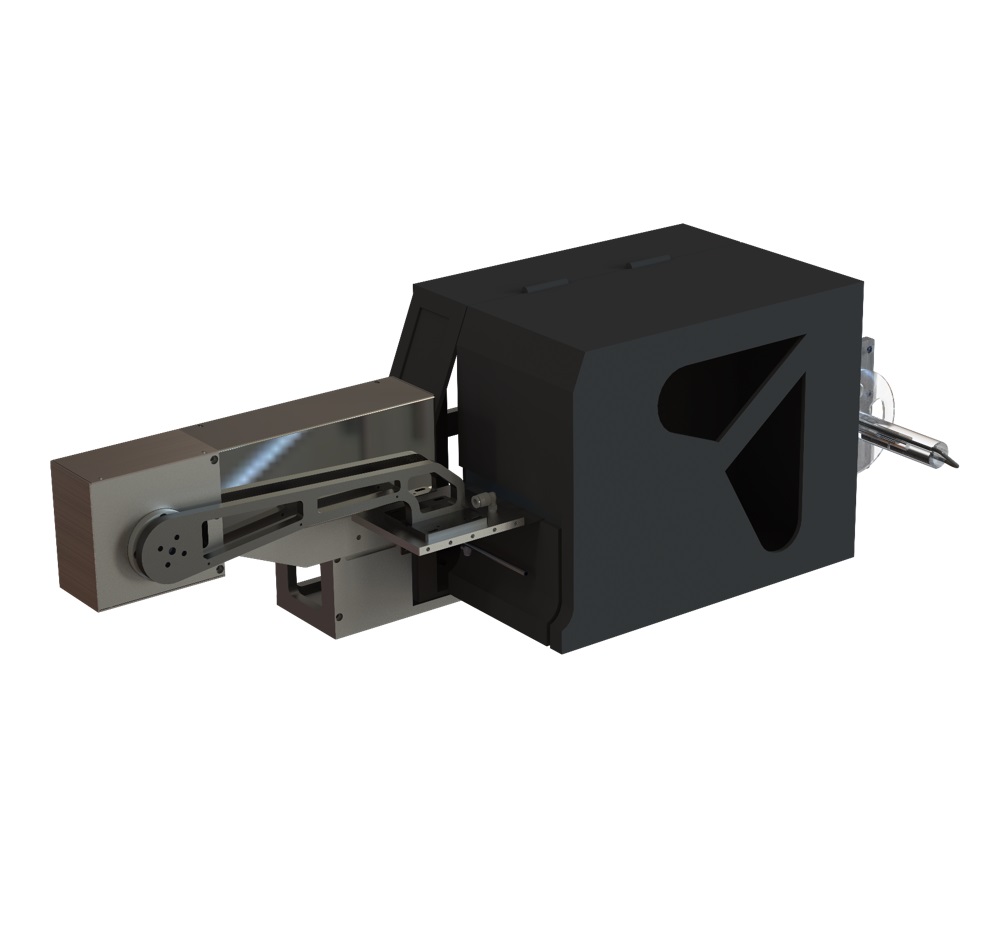

Operational features define the spectrum of functionalities dictating a swing applicator‘s adaptability within production workflows. The device employs swing-arm presentation, air-blow, vacuum placement, and swing-tamp mechanisms to suit different labeling needs. Compatibility extends to both stationary and moving product streams.

Operational controls offer customization. Print job storage allows quick label selection. Umbilical cords facilitate remote placement. A notable feature is the range of compatible print engines. It varies from 203 to 600 dpi to control the Print resolution according to pre-programmed parameters. This allows users to optimize print quality.

The swing applicator also integrates RFID encoding and verification, complying with EPC Gen 2 standards. Media consumption is optimized, alongside other features. All these help to increase efficiency and reduce downtime.

Automation Advantages

Automation advantages arise as a result of automating swing applicators within manufacturing environments. The incorporation of these systems provides significant labor optimization benefits, reducing dependency on manual labor for label application. Simultaneously, lower operating costs are attainable through automated label handling.

Error reduction is another key advantage impacting operational efficiency. Swing applicators minimize mislabeling risks through tightly controlled application processes. These systems guarantee consistent label positioning through coordinate-based alignment and eliminate human error in label handling. Integrating swing applicators improves processing speed and scalability, supporting high throughput. Throughput can be amplified further with tandem applicator configurations, raising overall productivity.

Furthermore, swing applicators precisely place labels on various surfaces, aided by automated package alignment systems. Using minimal-contact methods, label adhesion is maintained. Employing these automated methods ultimately improves cost efficiency by reducing material costs and eliminating pre-printed label expenses.

Tiếng Việt

Tiếng Việt