Choosing the perfect label printing technology: 9 important tips

In today's business environment, choosing the right label printing technology is critical to ensuring efficient and effective operations. To help you navigate this decision-making process, this article provides nine essential tips for choosing the perfect label printing technology. By understanding your label needs, assessing print quality requirements, assessing quantity and speed requirements, and considering label materials and sizes, you can make smart decisions that are right for you. with your business goals and maximize productivity.

Understand your label needs

Understanding your label needs is important before choosing the right label printing technology. This step is necessary to ensure you choose a solution that suits your specific requirements. When evaluating budget constraints, it is important to consider the long-term costs associated with label printing technology. While some options may have a lower initial cost, they may require expensive maintenance or have limited future capabilities. Therefore, it is important to analyze the barcode printing capabilities of the technology. Barcode printing is a fundamental aspect of many label applications, and it is important to choose a printing technology that can produce clear and accurate barcodes.

Also consider the volume and frequency with which your labels need to be printed. If you have high-volume printing requirements, you may need a technology that can process large batches efficiently. On the other hand, if you change labels frequently, a technology that allows for easy label design and quick printing may be more suitable. By carefully evaluating your budget constraints and analyzing your barcode printing capabilities, you can choose a label printing technology that fits your specific needs.

Evaluate printing quality requirements

To ensure optimal print quality, it is important to evaluate the specific requirements and expectations of the label being printed. When evaluating printer options, it's important to consider the device's resolution, color capabilities, and print speed. High-resolution printers often produce sharper and more detailed images, which can be important for labels with complex designs or small text. Additionally, considering your printer's color capabilities is important if your labels require bright and accurate colors. Some printers offer multiple color options such as CMYK or Pantone, allowing for more color customization.

Another factor to consider when evaluating print quality requirements is the printer's print speed. If you have a large number of labels to print, a faster printer can help improve productivity and efficiency. However, it is necessary to strike a balance between print speed and print quality to ensure that the label meets your requirements.

In addition to evaluating print quality, it is also important to analyze the cost-effectiveness of printer options. Consider the initial investment, maintenance costs, and cost per label when making your decision. It's important to find a printer that offers a balance between high-quality printing and cost-effectiveness to ensure you get the best value for your investment.

Evaluate volume and speed requirements

When evaluating label printing technology, assessing volume and speed requirements is critical to ensure optimal performance and productivity. Understanding the volume and speed limitations of different printing technologies is important in choosing the right one for your business needs.

Volume limits refer to the maximum number of labels that can be printed in a specific period of time. Printing in large quantities requires technology that can handle large quantities without compromising quality or slowing down production. Conversely, low-volume printing may not require the same level of speed and can be accomplished using simpler and more cost-effective printing technology.

Speed limits, in contrast, refer to the maximum speed at which labels can be printed. Some printing technologies are designed for high-speed production, allowing for quick completion and increased productivity. Other technologies may have slower printing speeds, which may affect the overall performance of the printing process.

Assessing volume and speed requirements is important to avoid production bottlenecks and ensure that your label printing technology can meet your business requirements. By understanding these limitations, you can make smarter decisions when choosing the perfect label printing technology for your specific needs.

In terms of Label Material and Size

After evaluating volume and speed requirements, the next important factor to consider when choosing the perfect label printing technology is label material and size. Label material and size play an important role in determining the overall effectiveness and durability of the label.

When it comes to label materials, choosing one that is appropriate for the intended application is important. For example, if the label will be exposed to extreme temperatures or humidity, choosing a material that can withstand these conditions is important. Additionally, consideration of label adhesive is important because it determines the label's ability to adhere to various surfaces. It is necessary to choose an adhesive suitable for the specific application, ensuring the label is held tightly and does not peel off easily.

Label size is another important factor to consider. It is important to determine the appropriate label size based on the content that needs to be printed on the label. Label size should be large enough to accommodate all necessary information while still fitting the desired surface.

Explore printing technology options

To explore print technology options for label printing, it is important to consider various factors such as print speed, resolution, and compatibility with different label materials. There are several printing technology options available on the market, each with its own advantages and disadvantages.

One of the most popular printing technologies used for label printing is thermal transfer printing. It provides high print quality and is compatible with a variety of label materials. However, this process can be slower than other technologies and requires the use of ink, which can increase the overall cost.

Another option is ink jet printing, which offers fast print speeds and color printing capabilities. It is flexible and can accommodate a variety of label materials. However, the print resolution may not be as high as other technologies and the ink may smudge or fade over time.

Direct thermal printing is another technology to consider. It offers fast printing speeds, high print quality and does not require the use of ink. However, labels printed using this method can fade easily and are easily damaged by high temperatures or sunlight.

When choosing label printing technology, it is important to consider factors such as required print speed, desired print quality, and compatibility with the label material. By carefully evaluating the pros and cons of different printing technology options, you can choose the option that best suits your specific needs and requirements.

Compare Thermal Transfer Printing and Direct Printing

Thermal transfer printing and direct thermal printing are two popular label printing technologies that offer distinct benefits and considerations. When comparing thermal transfer printing and direct thermal printing, it is important to consider factors such as durability, print quality and cost.

Direct thermal printing uses heat-sensitive paper that reacts to heat from the print head to create an image. This is a simple and cost-effective printing method because it eliminates the need to use ink or toner. However, direct thermal labels fade over time and can be easily damaged by heat, humidity or exposure to sunlight.

Meanwhile, thermal transfer printing involves applying a roll of heat transfer ink onto the label material. This method provides greater durability and fade resistance, making it ideal for applications requiring long-lasting labels. Thermal transfer printing also offers a broader range of label materials and printing options, including the ability to print in color.

When comparing costs, direct thermal printing typically has a lower initial cost because it does not require thermal transfer ink rolls. However, the operating costs associated with frequent label changes may be higher. Thermal transfer printing may have a higher initial cost due to the need to use heat transfer ink, but it can save costs in the long term, especially for high-volume printing.

Backup ink jet printing solution

When considering label printing technologies, inkjet printing solutions provide a flexible and high-quality option, building on the advantages and factors discussed in the previous subsection. Ink jet printing uses small nozzles to spray ink onto the label surface, creating precise and colorful prints. One of the main advantages of inkjet printing is its ability to produce high-resolution images and text, allowing for sophisticated designs and detailed product information. Additionally, ink jet printers can handle a wide range of label materials, including glossy, matte and textured surfaces, suitable for various industries and applications.

The cost factor for inkjet printing includes both initial costs and maintenance costs. Ink jet printers often require a higher initial investment than other printing technologies. However, they provide significant cost savings in terms of ink consumption and maintenance. Ink jet printers consume less ink during the printing process, leading to reduced ink costs over time. Furthermore, these printers often have self-cleaning mechanisms, minimizing the need for manual maintenance and minimizing downtime.

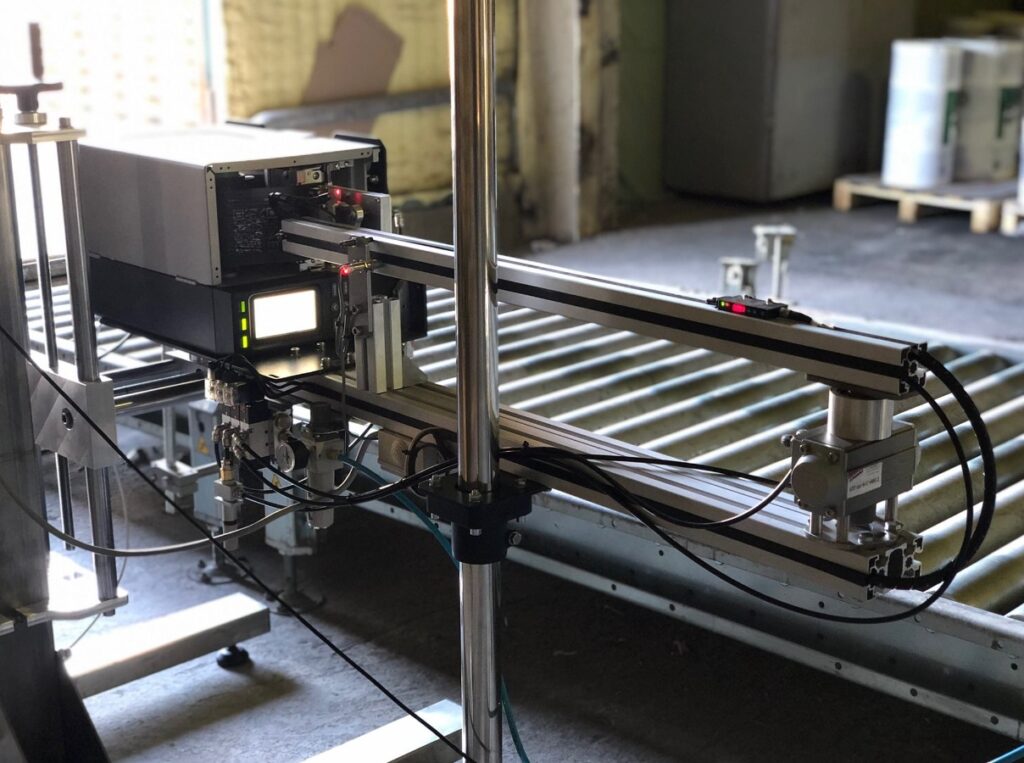

Integrate Label Printing Technology with Existing Systems

Integrating label printing technology with existing systems requires careful consideration and perfect compatibility to optimize operations and improve performance. Compatibility with existing systems is critical for smooth integration, minimizing disruption and maximizing productivity. However, challenges may be encountered during system integration.

One of the key challenges is ensuring label printing technology is compatible with existing software and hardware infrastructure. This requires a thorough assessment of the current system and identification of any potential conflicts or limitations. Adjustments or upgrades may be needed to ensure smooth integration.

Another challenge is data integration. Labels typically contain important information that needs to be synchronized with other systems such as inventory management or customer databases. Ensuring label printing technology can communicate and share data seamlessly with these systems is essential for accurate and up-to-date information.

Furthermore, training and support should be provided to employees to become familiar with new label printing technology and integrate it with existing systems. This will help minimize any interruptions or errors during the conversion process.

Conclusion

In conclusion, choosing the perfect label printing technology requires understanding your label needs, assessing print quality requirements, assessing quantity and speed requirements, and considering label materials and sizes. , explore printing technology options, compare thermal transfer and direct printing, explore ink jet printing solutions, and integrate label printing technology with existing systems. By carefully considering these factors, you can make smart decisions that meet your specific requirements and improve your label process.